♥ Sharing is caring ♥

DISCLAIMER: AS AN AMAZON ASSOCIATE I EARN FROM QUALIFYING PURCHASES. THIS POST CONTAINS AFFILIATE LINKS THAT WILL REWARD ME MONETARILY OR OTHERWISE WHEN YOU USE THEM TO MAKE QUALIFYING PURCHASES. FOR MORE INFORMATION, PLEASE READ MY EARNINGS DISCLAIMER.

Transformers produce a lot of heat during their operation, which must be dissipated to keep them working safely. This is achieved by various methods available to cool the transformers. Dry Type Cooling Method and Oil Immersed Type Cooling Method are the two most popular types of transformer cooling methods in the industry.

Transformers are extremely useful devices that convert high-voltage electricity directly from a power plant to a lower voltage. This helps machines and electronic devices that can only withstand low voltage to be used safely and effectively in places like offices, transit centers, colleges, factories, etc.

Dry Type Cooling Method

- Cooling by Environmental Air

- Cooling by Pressurized Air

Oil Immersed Type Cooling Method

- Cooling by Oil and Environmental Air

- Cooling by Oil and Pressurized Air

- Cooling by Pressurized Oil and Pressurized Air

- Cooling by Oil and Pressurized Water

- Cooling by Pressurized Oil and Pressurized Water

Dry Type Cooling Method

In the dry-type cooling method, the transformer does not have any liquid like oil or silicone. Such methods are used for transformers of lower voltage rating and in areas that have high moisture content.

Let’s discuss in detail the types of “dry-type cooling methods”.

1. Cooling by Environmental Air

This is the simplest method of cooling the transformers. In this method, the heat generated is dissipated by the natural convection method.

By means of the natural air convection process, the natural air (without using any fan) blows through the transformer’s body, hot air rises up, escapes the transformer’s body, and is replaced by the cold air. This method can be effectively used for low output transformers.

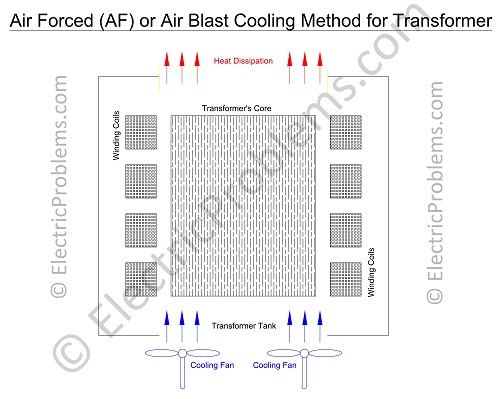

2. Cooling by Pressurized Air

When the transformer rating is larger than 1.5 MVA, natural air is not enough to cool the transformer. Then fans or blowers are used to push the pressurized air into the transformer’s core and winding. The air is fed into the transformer through air filters to avoid the flow of dust particles.

Fans or blowers are turned on automatically when the temperature of the windings and the core is increased to a specified value and also turned off automatically on reaching a suitable temperature.

Feel free to download a PDF file of this diagram.

In air-cooled transformers, the insulation used to keep the conductors from shorting together is typically a thin coat of varnish or enamel. Before the wire is wrapped around the core, it is coated with a thin varnish or enamel dye. This type of cooling method is effective up to a rating of 15 MVA of transformers.

Oil Immersed Type Cooling Method

Large power transformers with an oil cooling system are used in a variety of applications, like at large generating stations and substations to power delivery units. To provide cooling and insulation to these transformers, the windings and core are submerged in oil.

These transformers’ windings and cores are housed in a welded, oil-tight steel tank with a cover. The oil is used to transfer heat from the windings and the core to the metal tank and then into the air or surroundings.

The conductors of large power and distribution transformers are shielded from one another with oil-saturated paper or fabric. Oil-cooled transformers also have greater insulation and heat conductivity than air-cooled transformers.

Now we discuss in detail the types of oil-immersed cooling methods for transformers.

1. Cooling by Oil and Environmental Air

In this type, the winding and the core are immersed in an oil-filled tank. There is an arrangement of tubes that serves the purpose of the radiator.

When the temperature of winding is increased, oil gets hot and rises up by means of convection and fills the tubes. Here the natural air touches the tubes and escapes the oil heat out through the natural air convection process.

The cooled oil then moves downwards and recirculates in the transformer. The tubes increase the surface area of the tank so that oil circulates well and heat is given out from the transformer.

The oil in the transformer which is used for cooling purposes also serves as the insulation medium between coils. Transformers used in distribution lines usually use this type of cooling method that is HT/LT transformer like 11KV/110V.

Here is a PDF file of the diagram above.

Here is a PDF file of the diagram above.

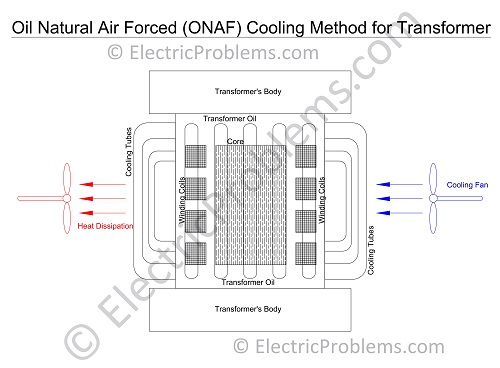

2. Cooling by Oil and Pressurized Air

This method is quite similar to “Cooling by oil and environmental air”. The oil uses natural convection but the air is forced. For this purpose, cooling fans are installed near the radiator tubes.

With the help of a fan or blower, high-intensity air is inserted into the radiator. This high-intensity air helps in cooling the oil in a faster and efficient way.

The fan or blower turns on automatically when the temperature of the winding and the core exceeds the specified temperature and is also turned off automatically.

The addition of fans or blowers increases the overall transformer cost. This method is commonly used for large transformers up to 60 MVA where more heat is produced and quick cooling is required.

You can check out this PDF file for more detail.

3. Cooling by Pressurized Oil and Pressurized Air

In this type of cooling method, a heat exchanger or radiator is fitted with the tank of the transformer. A pump is also there through which high-temperature oil is circulated and air blast is fed into the heat exchanger to achieve quick cooling.

This process is somehow similar to cooling by oil and environmental air as long as the transformer is not overloaded. But when the transformer is overloaded and is heated to a specified temperature, then sensors give an alarm, and the oil pump and fans are turned on automatically.

The pump enhances the oil flow circulation and the air is forced to pass through the heat exchanger with the help of high-speed fans. Thus, quick cooling takes place by pressurized oil and pressurized air cooling methods.

This type of cooling system is used in substations and power stations where higher rating transformers are used.

Here is a PDF file of the above picture (schematic).

Here is a PDF file of the above picture (schematic).

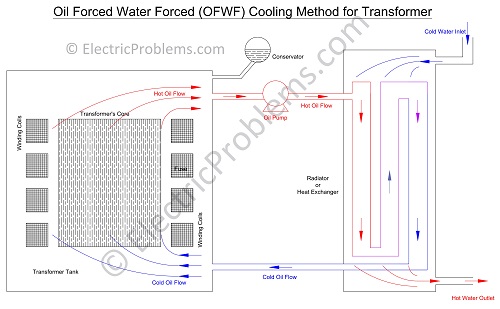

4. Cooling by Oil and Pressurized Water

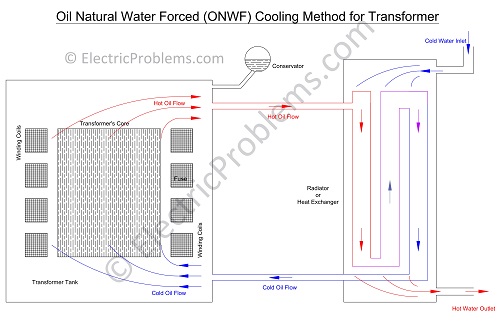

In this type of cooling method, the heat exchanger is installed outside the transformer, and the transformer tank is filled with oil. Winding and the core are dipped in this oil. As the transformer’s temperature is increased the oil becomes hot, then hot oil rises up through the natural convection process and goes to the radiator or heat exchanger chamber.

Then cold water is forced into the heat exchanger, heat is dissipated out from the oil. Cold oil recirculates to the transformer again. Hot water is drained out from the heat exchanger through an outlet.

Here is a PDF file of this cooling method.

Here is a PDF file of this cooling method.

5. Cooling by Pressurized Oil and Pressurized Water

In this method instead of the natural flow of oil, pumps are used to flow the pressurized oil as well as water and fed to a heat exchanger or radiator which cools down the oil.

Here we have to keep the pressure of oil more than the pressure of water. This is due to the reason that if any leakage happens in the oil pipe and the pressure of oil is high then there is a chance of mixing the oil with water, this thing prevents the mixing of water with the oil.

Because the pressure of water is more than the pressure of oil then water leaks into the oil and reaches the transformer windings then the insulation of transformer windings breaks down and there is a danger of burning the transformer windings.

This high-performance method is most suitable for very large rating transformers. These high rating and heavy-duty transformers are used at places where electrical power is generated and then fed to transmission lines.

This PDF file is for the schematics pictured above. You can also download ALL schematics in one PDF file.

Hope this information clarifies the cooling methods of the transformers. If you have any questions, feel free to leave a comment.

Click on the white button above to find your electrician!